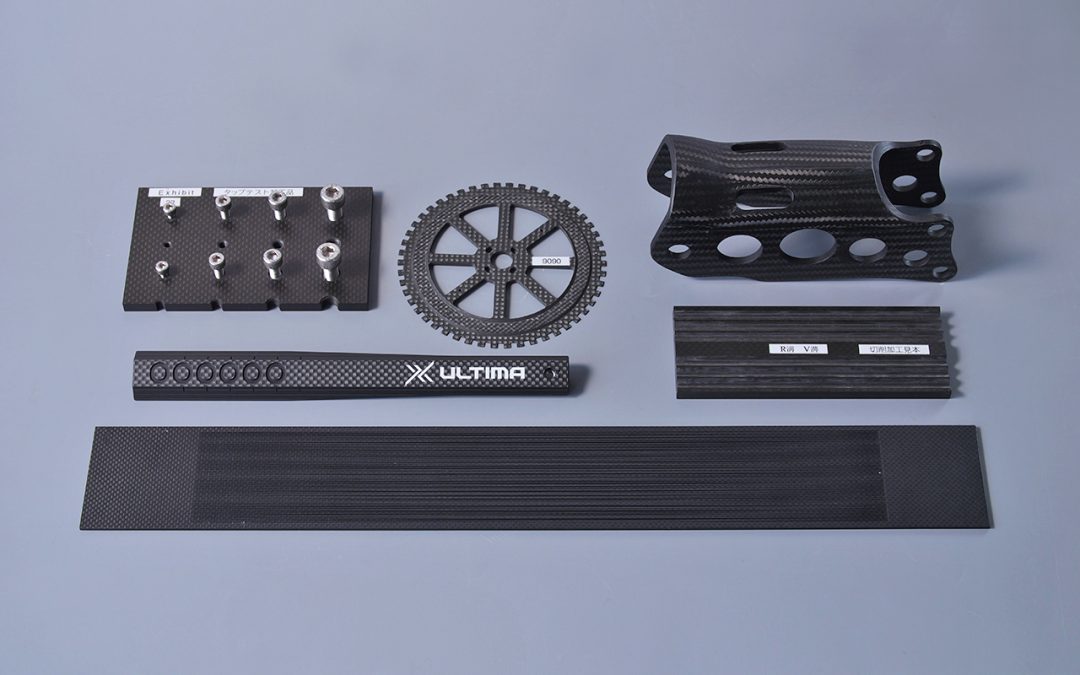

Products

CFRP Processing

CFRP is a material that has been attracting attention in recent years for its light weight, high rigidity, chemical resistance, electrical conductivity, and low thermal mutation.However, due to its material properties, it is difficult to machine like ordinary metals and requires different ingenuity.

We have been working on the machining of CFRP materials since 1983 and have delivered several processed products.

This arm is used to supply CDs to CD manufacturing machines, and CFRP is used to reduce the weight of the arm and enable it to supply CDs at higher speed. Conventional cutting process with end mills are not suitable for the finish and cost, so we use tools developed by our company.

Rotating disc for lapping machine (image on the right)

This disc is used for the rotating part of a lapping machine, so it needs to be lightweight and strong.

A nozzle part used for the ink outlet of a printing machine. A series of holes 1.5 mm in diameter are drilled in a pipe-like material. If the part is drilled in the usual way, the tooling is not durable, and the cost is high in terms of tooling cost and time required to replace the tooling.

Medical-related equipment (image below)

CFRP is now also used in medical devices, and the product in the photo on the right is used in place of a splint in the case of a bone fracture.

The roller of a steel printing press is made of CFRP, which is lightweight and can be replaced by one person, contributing to labor savings and power. Only the attachment parts at both ends are made of steel, and CFRP formed into a pipe shape is bonded to the steel and the outer diameter is machined with a cylindrical grinder. The overall length of the product is less than 2 m and the concentricity must be within 4/100 of a millimeter, so we also manufactured our own measuring machine for this product.